Abu Dhabi, UAE

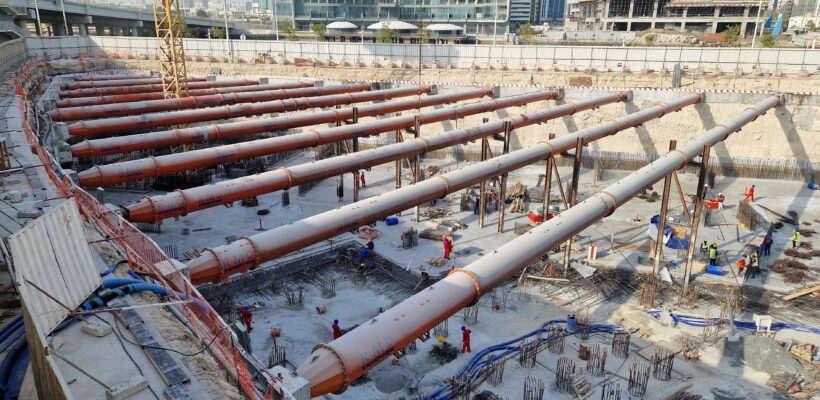

Altrad RMD Kwikform has supplied a ground shoring solution to support a challenging large-scale excavation in Abu Dhabi in the Middle East – one of the largest excavations in the company’s history, featuring a maximum depth of 14.25m, and approximate volume 111,050 m3.

The Tubeshor solution was chosen for its ease of use and installation, improving productivity on site while mitigating the risks posed by the challenging site environment.

The sheer size of the mixed-use development presented a significant engineering challenge. Traditional shoring methods would have required a large number of props, resulting in high material costs and reduced workspace within the excavation site. Given the scale and complexity of the excavation, the contractor required a system that could be assembled and disassembled quickly to maintain the project timeline.

What’s more, the project is situated next to water, which posed logistical and environmental hurdles. The proximity to the water required careful planning to prevent contamination as well as mitigating risks associated with flooding and erosion.

For this excavation, Altrad RMD Kwikform provided 387t of Tubeshor material consisting of 24 Tubeshor props, each with a 1060mm diameter, specifically designed for heavy-duty applications. The Tubeshor system’s strength and modular design made it the ideal solution for the project’s complex requirements.

The props had a maximum span of 67m and a prop spacing of 7.5m, which was then supported by a single plunge column along its length, with the equipment on site for over 12 months. Weldable stub ends were used on one end of the prop to reduce welding and installation time on site, while allowing for a certain amount of length adjustment.

The use of Tubeshor components enabled a value-engineered strutting design, which brought significant benefits to the project. By utilising high-strength S460 steel, the Tubeshor system provided exceptional structural support giving unprecedented axial load capacity, with the maximum load acting on the prop of 3295kN.

Large-scale excavation

It was situated next to water, which posed logistical and environmental hurdles. The proximity to the water required careful planning to prevent contamination as well as mitigating risks associated with flooding and erosion.

387t of Tubeshor material consisting of 24 Tubeshor props, each with a 1060mm diameter.

This also offered a 30% reduction in the amount of steel needed, not only lowering costs but also maximising the available excavation space, allowing contractors to work more efficiently. Bolted connections also improved the ease of use and reduced installation and dismantling time.

The ability to easily adjust and reconfigure the props on-site meant that the system could be tailored to meet the specific needs of the excavation as it progressed. The original customer design had featured 28 plunge columns, but the team were able to reduce this to 10. This flexibility reduced the time and effort required for assembly and adjustments, streamlining the project.

Vijay Patil, Lead Engineer for Altrad RMD Kwikform in the Middle East & India said:

The implementation of our Tubeshor system on this mixed-use development project has had a profound impact on the delivery of this excavation. Its strength, design and efficiency ensured the team stayed on schedule and within budget.

The sheer scale of the project showcases Tubeshor’s engineering and adaptability in providing robust and efficient support for complex construction projects, and this is one of the largest excavations in Altrad RMD Kwikform’s history.