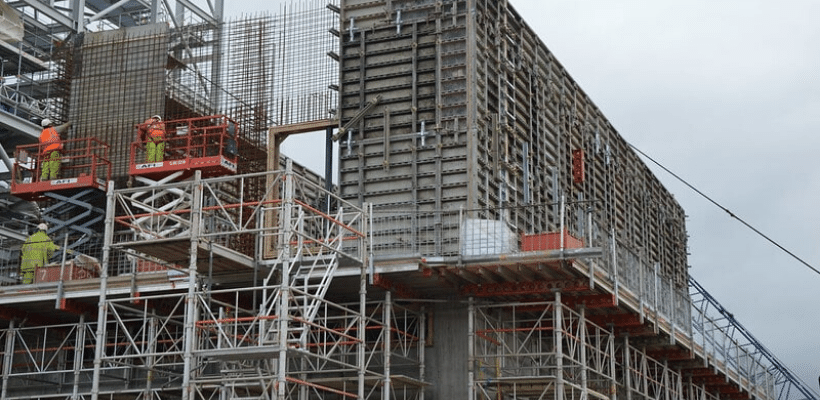

Formwork and falsework solutions for LNG facilities

For LNG (liquefied natural gas) sites, the scale of works for formwork and falsework is enormous. Altrad RMD has extensive knowledge and experience in providing solutions across a number of projects in this industry.

The vast height and width of concrete structures involved in LNG construction often requires formwork solutions that can withstand large volumes of pressure, particularly if short cycle times are required. We have engineered systems that can withstand pressures up to 166 kN/m2 and can create bespoke solutions where required.