An evolution of Tubeshor, the Tubeshor Active Thermal Compensator (ATC), is a revolutionary patent protected Tubeshor accessory that can reduce thermal loading by up to 90% compared to a mechanically locked off prop.

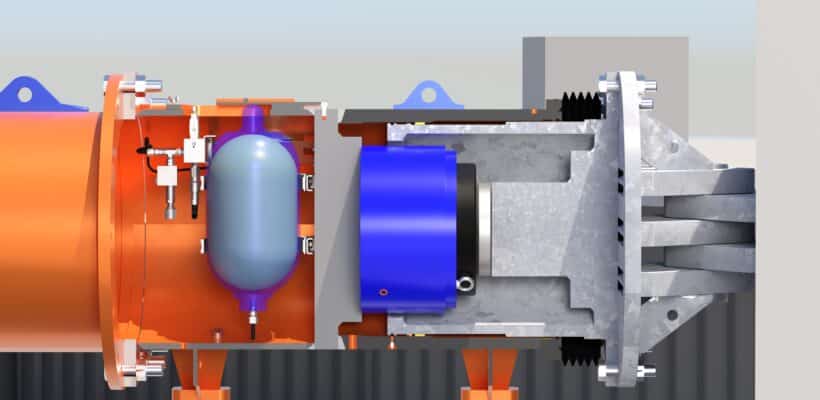

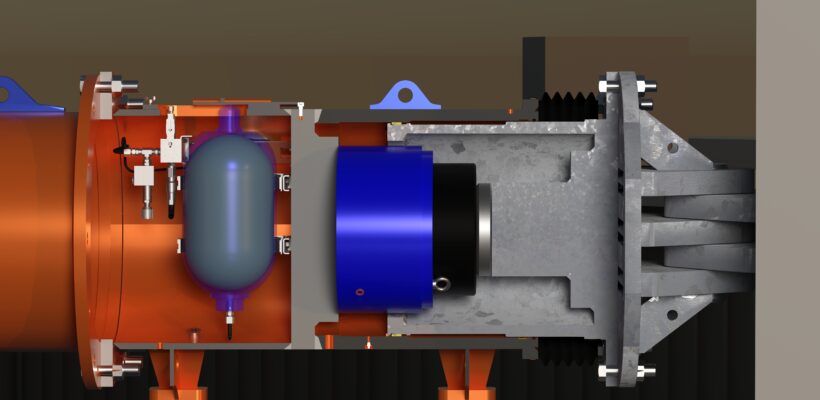

The Tubeshor ATC contains a 450tonne load capacity hydraulic cylinder coupled to a bladder accumulator which is pressurised to suit the individual prop and design geo-load before dispatch. Most of the time, the pressure of the hydraulic cylinder will be less than the pressure in the accumulator - which results in normal/static performance of the prop.

When higher temperature forces excessive prop thermal expansion which causes the pressure in the hydraulic cylinder to be greater than the accumulator, the gas within the accumulator will automatically compress to balance out the pressures. This means that a further increase in prop length resulting from thermal expansion does not result in nearly the usual increase in prop load.

Learn how the system works in the video below: